Orbital Tube Welding

When the need arose in the marketplace for welding of highly critical aircraft hydraulic lines made of 21-6-9 stainless steel tubing, we added “orbital tube welding” to our services in 2006. And now we are approved to Boeing BAC 5974!

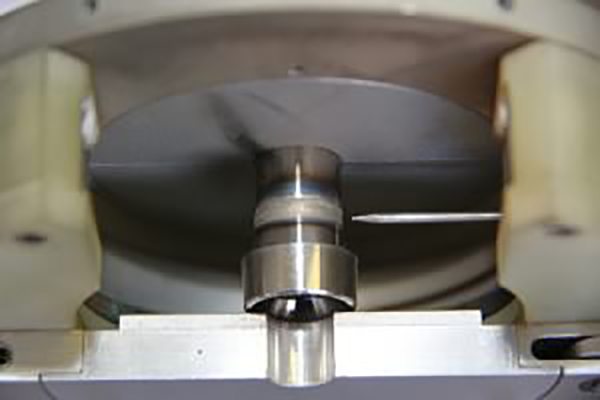

Orbital tube welding uses the same process as GTAW/TIG, but the work is performed by a machine, rather than by hand. This process works extremely well in applications that require radiograph inspection with very tight tolerances.

Our company’s precision craftsmen and orbital tube welding machine are qualified by being tested to AWS D17.1. We’re qualified to weld the following materials:

- Stainless Steels

- We can also qualify for other materials if you need

These welder qualifications allow us to certify the welds to AWS D17.1, P8TF3, and others. Now approved to Boeing BAC 5974.

3/8” OD X .028 wall welded orbitally.

1/2” OD X .028 wall tube welded orbitally.

“Dan’s Certified Welding Inc is considered one of the Number One Vendors that we have. We have been doing business with them since 1985 and year after year the great customer service we receive from them never changes. Their quality work is far superior to other shops we hve used for our aerospace application. We manufacture aerospace tube assemblies for commercial airlines and rely on DCWI to provide qualty welding that will standup to the stringent guidelines of the Aerospace Industry. Reuben’s constant care to our needs and requirements make his company a great asset. We here at Arrow Engineering would recommend DCWI to anyone.”

– Julie Teeter Office Manager

Arrow Engineering Inc., Irwindale, CA.

You MUST Ask BEFORE Hiring a Welding Company – So You Can Avoid Wasting Your Time AND Hard-Earned Dollars”

You MUST Ask BEFORE Hiring a Welding Company – So You Can Avoid Wasting Your Time AND Hard-Earned Dollars”

No Comments