Micro TIG Welding

“MICRO TIG WELDING” takes the Gas Tungsten Arc Welding (GTAW)/ Tungsten Inert Gas (TIG) process to whole new level of surgical precision. This process is frequently used in the mold industry, where repairs often must be done with minimum weld buildup.

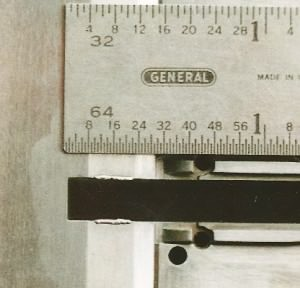

In micro tig welding, the weld is performed using a microscope and a custom small tig torch. The filler material wires used in this process can go down to .005” (5 thousands of an inch). The use of the micro tig process is critical to the repair of molds, since it leaves minimal to non-existent sink. (“Sink” is evidence of the weld where the section next to the weld is lower and then rises back up to the original height of the material.)

Pre-heat and post-heat furnaces are used as required, to help prevent the tool steels from cracking. The filler materials are purchased to match the base metal material and/or match the base metal hardness.

MICRO TIG WELDED EDGE

MICRO TIG WELDING ON RIBS

“DCWI has helped us with many of our mold repairs. Their knowledge and performance in welding all types of tool steel has save us a lot of time and money with our tool reworks. The have great attention to detail and quick response time, which is so important in our line of work. I really appreciate DCWI’S help.”

– Paul May-Geiger Plastics

Aside from the mold industry, the micro tig welding process also works extremely well in the aircraft industry, where parts must be made from very thin materials. We weld on hundreds of parts that are only .016 thick. These parts are highly critical, as the largest defect allowed when radiograph inspected is .005.

We added micro tig welding to our services in 1999, and have since established lasting relationships with our loyal, highly satisfied customers. If you need high-quality micro tig welding done on time, every time – just fill out a FREE Request for Quote (RFQ) form with your job details or fax at (562) 803-9529. We’ll send you a quote as soon as possible.

“I am the owner of Hefner Mold Co.and have been in business for over 40 years. We specialize in Plastic Injection Molds. Over the years we have used many welders. I am very satisfied with all the work that Dan’s Certified Welding Inc has done for us. I am particularly happy with DCWI’s Micro Welding a type of welding that is not available at most welders and is critical for the weld I require.”

– Jerry Hefner- Hefner Mold Co.

You MUST Ask BEFORE Hiring a Welding Company – So You Can Avoid Wasting Your Time AND Hard-Earned Dollars”

You MUST Ask BEFORE Hiring a Welding Company – So You Can Avoid Wasting Your Time AND Hard-Earned Dollars”

Keep in Touch